How to effectively prevent backflow of stainless steel sanitary check valve

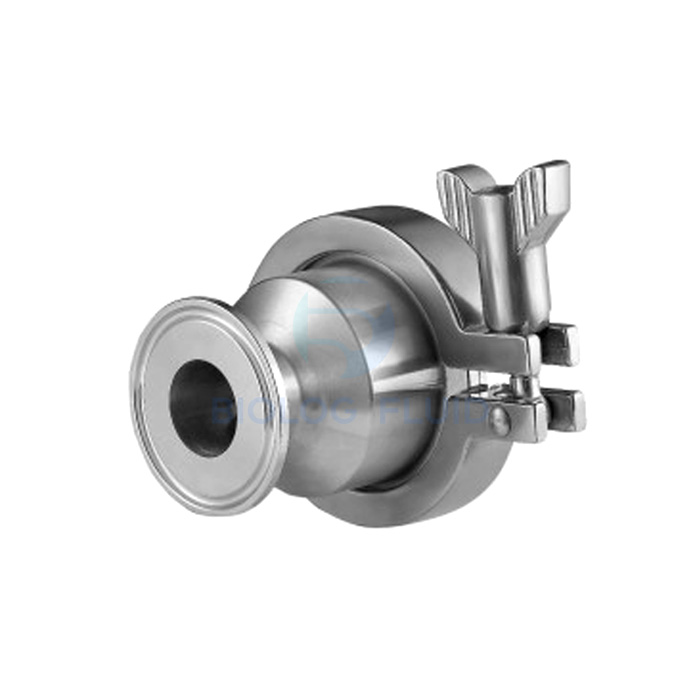

2024-09-03Stainless steel sanitary check valve is a critical fluid control device that ensures one-way flow of fluid in pipelines and prevents backflow. Reverse flow is highly undesirable in many industrial processes as it may lead to pollution, energy waste, and system failures. Therefore, understanding how stainless steel sanitary check valves effectively prevent backflow is crucial for maintaining the operational efficiency and safety of industrial systems.

1. Design a reasonable structure

The structural design of stainless steel sanitary check valves directly affects their ability to prevent backflow. A good design should include the following aspects:

Firstly, sealing is a fundamental element in preventing backflow. High quality sealing materials should be used inside the valve to ensure complete isolation of fluid flow in and out when closed. At the same time, valve seat seals should also be made of high-density silicone or PTFE materials to ensure effective sealing in high temperature or high pressure environments.

The valve should have a sufficiently large cross-sectional area inside to ensure that there is no excessive flow resistance when the fluid passes through the valve. A high flow resistance can lead to pressure loss, thereby increasing the possibility of backflow. Therefore, in the design, flow resistance should be minimized as much as possible to improve the efficiency of fluid passing through the valve.

Then, the opening and closing mechanisms inside the valve should also be designed reasonably to ensure that the valve can quickly and accurately respond to changes in the fluid. A common design is to use a spring return mechanism, which can provide sufficient sealing force when the valve is closed, while not interfering with the normal flow of fluid.

2. Regular maintenance and overhaul

In addition to good design, regular maintenance and overhaul are also key to ensuring that stainless steel sanitary check valves effectively prevent backflow. During use, there may be issues such as wear and scale buildup inside the valve, which can reduce its sealing performance and increase the risk of backflow.

Therefore, regular maintenance and overhaul are essential. This includes cleaning the dirt inside the valve, replacing worn seals, inspecting and adjusting the spring mechanism, etc. It is also necessary to regularly check the working status of the valve to ensure that it can accurately respond to changes in the fluid and promptly correct any abnormal phenomena.

3. Choose suitable materials

The material selection of stainless steel sanitary check valves is also an important factor in preventing backflow. In many cases, the medium may contain corrosive substances or special requirements such as high temperature and high pressure, which ordinary materials may not be able to meet.

Therefore, when choosing stainless steel sanitary check valves, appropriate materials should be selected based on the characteristics of the medium. Usually, stainless steel is a good choice because it has good corrosion resistance and mechanical strength. Other materials can also be selected according to specific requirements, such as titanium alloys, nickel based alloys, etc.

The design, maintenance, and material selection of stainless steel sanitary check valves are key to ensuring their effective prevention of backflow. By rational structural design, regular maintenance and overhaul, and appropriate material selection, the risk of backflow can be greatly reduced, ensuring the operational efficiency and safety of industrial systems.